800-1000kg/h high density Wood Pellet Production Line /wood pellet

mill

Product Description

Sawdust pellet machine refers to a new type of clean fuel that can

be directly burned in granular form by mainly using agricultural

and forestry waste such as sawdust and straw as raw materials,

through crushing, drying, additive mixing, extrusion and other

processes. It can be used as coal, Traditional energy alternatives

such as diesel and natural gas.

Introduction of wood chip production line:

The wood pellet machine production line is developed by our company

to establish an industrialized production line for biomass

production. The complete set of equipment for wood pellet machine

mainly includes: pulverizer, dryer, granulator, conveyor, cooling

machine, packaging machine. The production of wood pellets consists

of raw materials, crushing, drying, granulation, cooling, and

finished product packaging. Every step of each equipment has strict

operating specifications and quality requirements to ensure product

quality.

Equipment needed:

log receiving and slicing system - crushing system - drying system

- pelletizing system - cooling system - screening system -

automatic packaging system

Process flow of wood pellet machine production line:

Sub-sieving: Screening to remove oversized materials and impurities

to ensure that the raw materials meet the granulation requirements.

Generally between 2-6mm.

Drying: Biomass fuel granulation requires less than 20% moisture,

and the moisture is dried with a tumble dryer.

Granulation: The key step is completed by a biomass pellet machine.

Zhongdebao pellets are of high quality and stable and high yield.

Cooling: Due to the extrusion work, the temperature of the biomass

particles is relatively high, so they need to be cooled before

packaging. Counterflow cooling machine, reasonable design, rapid

cooling.

Screening: Qualified biomass particles are screened out through a

vibrating grading sieve, and other unqualified products are

recycled for reuse.

Packaging: automatic measurement, automatic sealing, saving time

and effort, improving efficiency and reducing costs.

The dust removal equipment recycles the dust generated during the

production process for granulation, reducing waste and increasing

income.

Technical Parameters:

| Model | Power | Capacity for wood pellet | Net/Gross Weight(kg) |

ZLSP-R550B | 55KW 380V 50HZ | 800-1000KG/H | 1800-1890kg |

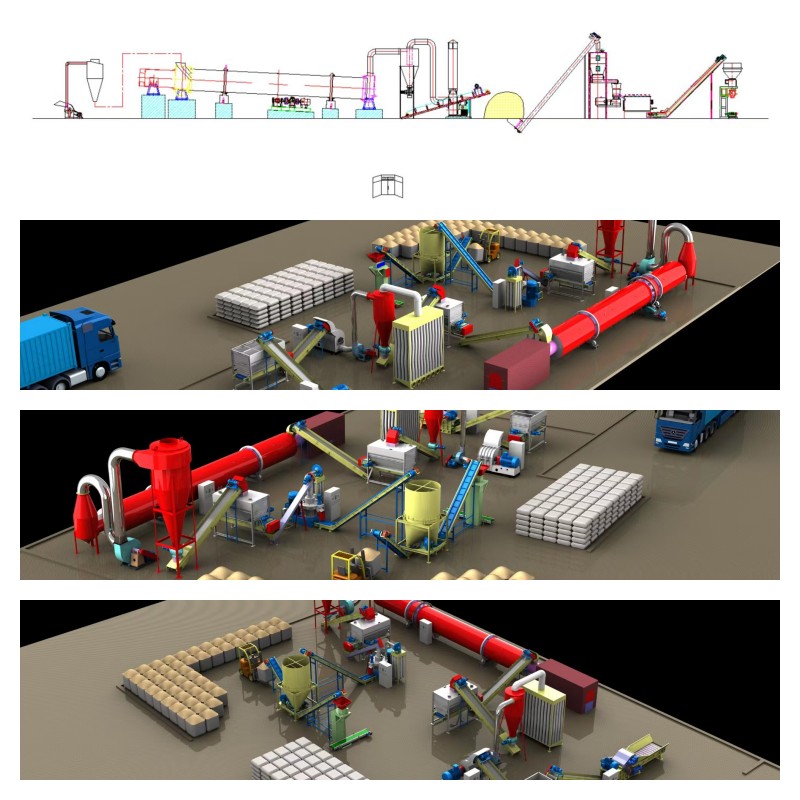

Flow Chart:

Some cases of our export abroad

Applications:

Production line related equipment

Packing and Shipping :

If you are interested, please email us